Servicing

I thought a recent locomotive service would be of interest. The model drew over 1A with the wheels barely turning 1 RPM, let’s have a look.

You can see 3 different grease in the gearboxes, green, the white goop then a mountain of thin bearing oil to really mix it all together. As pictured, the grease is a chewing gum consistency, all these different greases are likely incompatible with each other. The gearbox on the left has been stripped and cleaned.

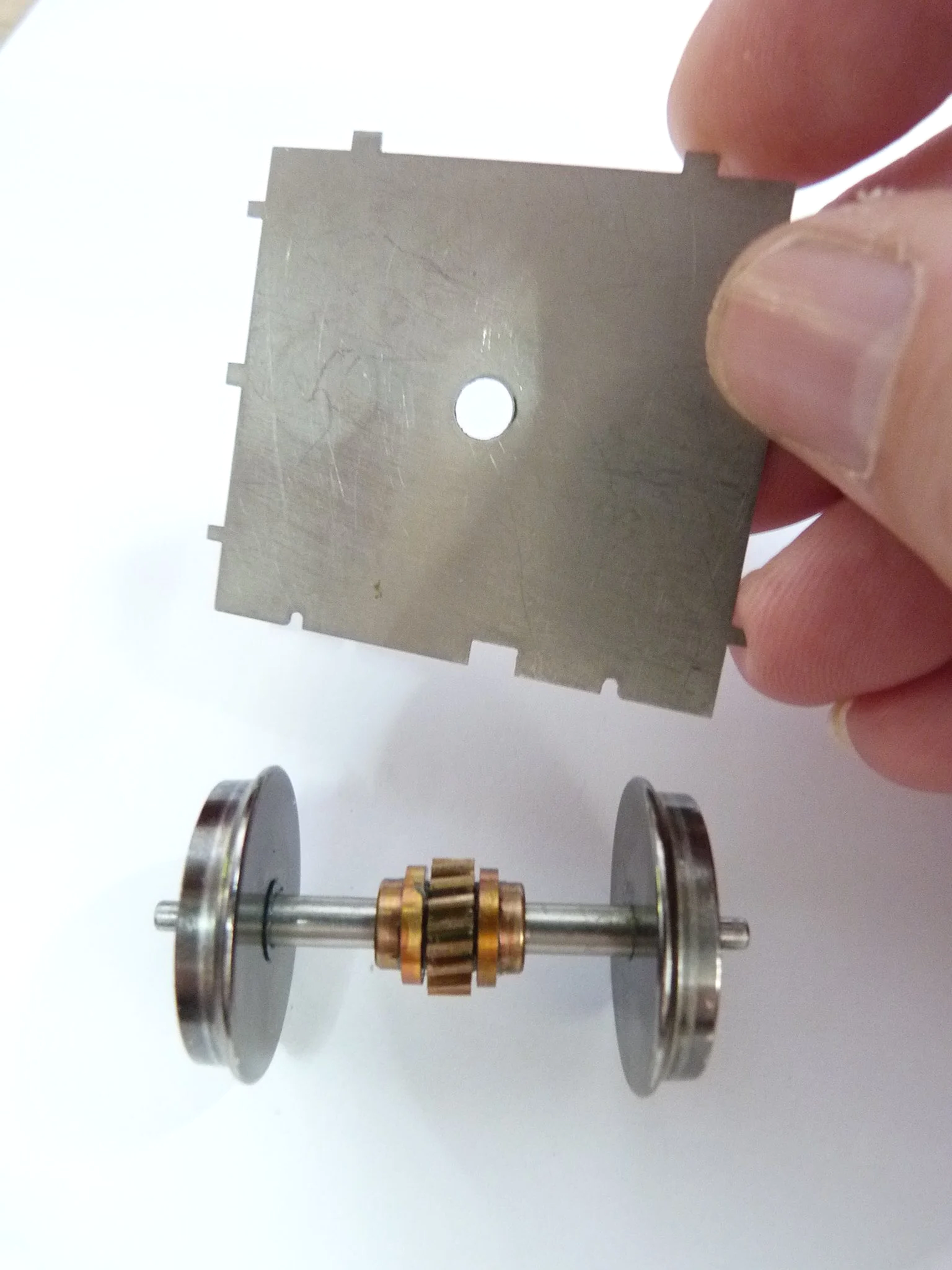

While I am here... These drive shafts do not have thrust washers. On they go, don't forget to measure the location of the worm that needs to be pressed off ---before--- you do!

Verify wheel gauge while here, never assume this is correct. Use the correct gauge/measurements... If a gauge isn't available use a vernier to verify against published standards..

Last photo... The top axle has had it's first clean, it needs another one or two. With wheel sets I clean by hand using a minimum of product due to the plastic bosses,, I have never had one fail/crack, I'm not about to test my luck either. What you can't see is ultimately where the seizing occurred, the grease had seized these bearing pairs on 5 out of the 8 trucks I inspected...